- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

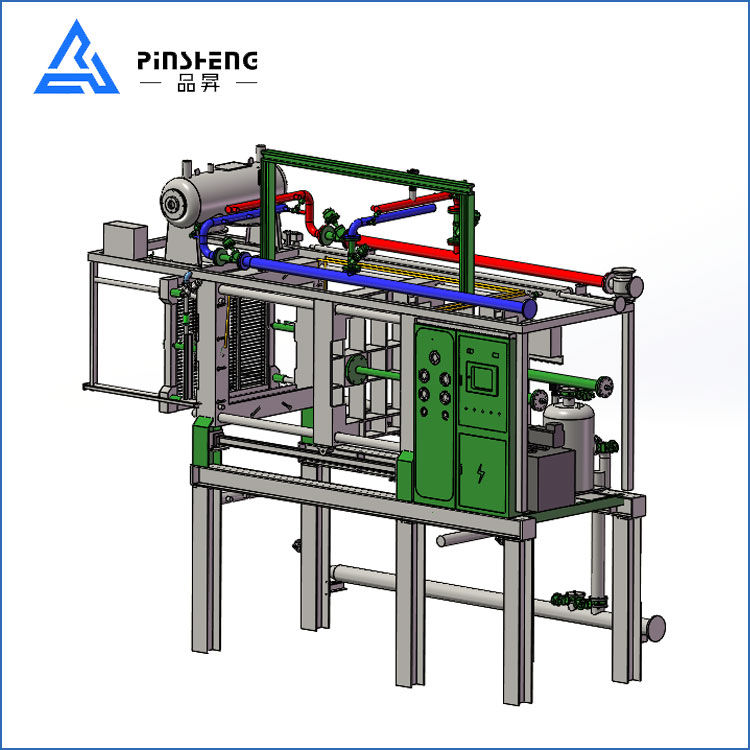

EPS Automatic Vacuum Shape Molding Machine

We are delighted to introduce our Pinsheng® hot sale machine, the EPS Automatic Vacuum Shape Molding Machine. With over 10 years of experience in manufacturing and selling, we are dedicated to providing you with a high-quality machine and excellent after-sales service.At our firm, we believe in controlling the standard by paying attention to details and demonstrating our power through quality. We have strived to establish an extremely efficient and stable team of employees and have explored an effective and excellent command method for our high-quality low-price EPS Automatic Vacuum Shape Molding Machine. We are committed to meeting your requirements and sincerely look forward to developing a mutually beneficial business relationship with you.

Send Inquiry

Our high-quality low-price EPS Automatic Vacuum Shape Molding Machine is equipped with advanced production and processing equipment, along with skilled workers, to ensure the merchandise is of the highest quality. We provide excellent before-sale, sale, and after-sale services to ensure that customers can confidently place their orders. Our machines are in high demand and are popular in regions such as South America, East Asia, the Middle East, Africa, and more.

The Pinsheng® EPS Automatic Vacuum Shape Molding Machine is constructed with good quality steel plates that ensure durability for many years. With a reliable steam system and qualified accessories, our machine achieves high efficiency and low energy consumption.

Model:PSSM1412

Brand: PinSheng

Product Parameter (Specification)

|

1.Mechanical structure |

Our EPS Automatic Vacuum Shape Molding Machine utilizes good quality steel plates, with all formwork tempered at high temperature and shot peened at high pressure. This results in high strength and surface hardness. All templates are processed using CNC technology to ensure precision. |

|

2.Steam System |

Our EPS Automatic Vacuum Shape Molding Machine is equipped with a long-range control system and a reducing valve to stabilize steam flow, with a control accuracy of ±0.2 Bar. |

|

3.Electrical control |

The electrical control of our EPS Automatic Vacuum Shape Molding Machine incorporates globally recognized components, including a Taita touch screen and Schneider brand low-voltage electrical appliances. The steam pressure, main steam pressure, demoulding, air cooling, and pressurized feeding all adopt a remote pressure regulating system, where valves open and close according to the set pressure ratio, making operation easy.

|

|

4.Hydraulic System |

A digital encoder is employed in the EPS Automatic Vacuum Shape Molding Machine to control the stroke distance of mold opening and clamping. This ensures the safety protection function of the mechanical, hydraulic, and electrical systems, meeting safety standards. |

Product Feature And Application

The Pinsheng® EPS Automatic Vacuum Shape Molding Machine is widely used to produce various EPS products, including vegetable boxes, fruit boxes, fishing boxes, household appliance packaging, and more..

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time of EPS Automatic Vacuum Shape Molding Machine?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts of EPS Automatic Vacuum Shape Molding Machine from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.