- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

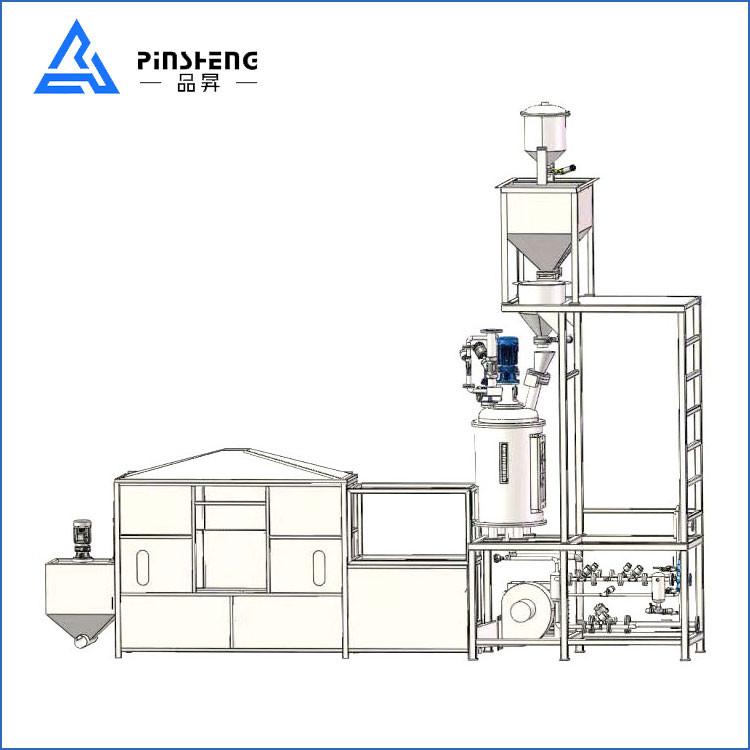

EPS Batch Type Pre-Expander Machine

Ningbo PinSheng Machinery Co., Ltd. is a professional manufacturer of EPS machines and molds based in China. We specialize in manufacturing and selling a range of EPS machines, including EPS Pre-Expander, Pinsheng® EPS Batch Type Pre-Expander Machine, EPP machine, ETPU machine, and EPS molds. Our products are not only popular in the domestic market but also trusted by clients worldwide. We offer superior quality machines at competitive prices, making us a great choice for those interested in the mentioned machines and molds.

Send Inquiry

We believe that boosting our EPS Batch Type Pre-Expander Machine and providing excellent service is the key to success. Our mission is to offer innovative products and solutions that provide customers with an exceptional experience. We have a strong focus on top-grade, cheap-priced EPS Batch Pre-expander Machine. We look forward to establishing a long-lasting and mutually beneficial cooperation with you in the future.

The EPS Batch Pre-expander Machine we offer comes with several advantages. It ensures stable feeding speed, high production efficiency, stable density, good foam quality, and low steam consumption.

In summary, the Pinsheng® EPS Batch Type Pre-Expander Machine offered by Ningbo PinSheng Machinery Co., Ltd. provides stable performance, high production efficiency, and superior foam quality. Our machines are suitable for producing a wide range of EPS products that find applications in different industries.

Model:PSPEB-N70/150

Brand: PinSheng

Product Parameter (Specification)

Our Pinsheng® EPS Batch Type Pre-Expander Machine includes common dryer bed, screw conveyor, filling, and sieving devices. Our Batch EPS pre-expander helps minimize operating errors.

|

1.Steam System |

The EPS Batch Type Pre-Expander Machine is equipped with a steam system reducer and an angle valve control system. This ensures proper machine operation and the production of high-quality EPS foam beads. |

|

2.Filling System |

Thanks to the electronic weighing system, the EPS Batch Type Pre-Expander Machine can achieve automatic feeding by simply setting the desired weight on the touch screen. |

|

3.Material Level Control |

A photo sensor is used to control the expansion level of the material during the pre-expansion process. |

|

4.Electric Control |

With the PLC and Touch Screen, the entire process of the EPS Batch Type Pre-Expander Machine can be realized automatically. |

Product Feature And Application

Pinsheng® EPS Batch Type Pre-Expander Machine is considered the best choice for producing EPS products. EPS is widely used in various areas of life, such as packaging for household products, fishing boxes, and insulation boards for construction.

Deliver,Shipping And Serving

FAQ

1.Where is your factory located?

We have 2 production plant, one plant locates in Hangzhou which professionally producing EPS/EPP/ETPU machine. Another factory locates in Jiangsu Provide which producing EPS/EPP/ETPU mould. Both two factories are pretty close to the Shanghai port for easiest transportation.

2.Do you have detailed and professional installation manual?

We will provide very detailed installation manuals and videos, and the service until you are satisfied

3.Are you a trading company or a manufacturer?

We are manufacturer.

4.Q:How long is your delivery time of EPS Batch Type Pre-Expander Machine?

Normally delivery time is 30~45 days.

5.Q:How many years have your company made this kind of equipment?

More than 10 years.

6.Q:Can I only buy some spare parts from you?

Yes, we also provide all kinds of spare parts that relatives to our machine.

7.How do you pack the equipment EPS Batch Type Pre-Expander Machine?

We will strengthen and protect the equipment to ensure that they will not be damaged during transportation.

8.Q:Can you send your staff to install the equipment for us?

Under normal conditions, it is possible. Now it is an epidemic situation. We will try our best to assist in case wecannot send technician in time. We will also conduct video connections with guests to teach them to install them in place.

9.Q:Can you can design the equipment according to our size?

Yes, it is acceptable

10.Q:How many production lines in your factory?

We have total 10 production line.